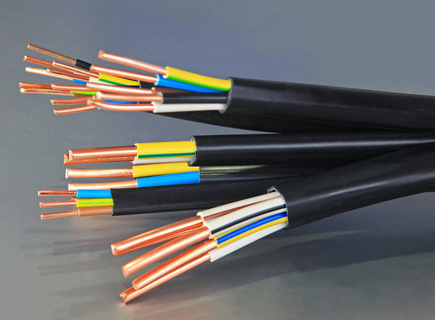

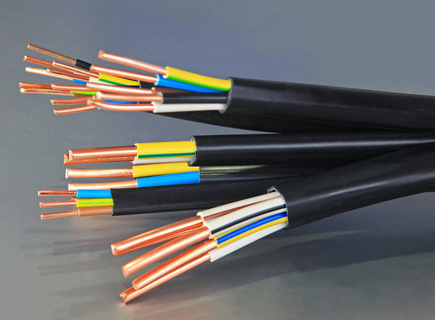

Different uses of polyvinyl chloride (PVC) plastics in the wire and cable industry

Published:2022-10-07 Views:329

PVC plastics are multi-component plastics, and different varieties of PVC plastics for wire and cable can be made by changing the varieties and dosages of compounding agents according to different conditions of use. PVC cable plastic can be divided into insulation grade cable material and sheath grade cable material according to its use in wire and cable. 1、PVC plastic for insulation According to the requirements and characteristics of wire and cable, the types, performance, requirements and main uses of PVC plastic for insulation are divided into insulation grade, general insulation grade, heat-resistant insulation grade, high electrical performance insulation grade, oil and solvent resistant insulation grade, flame retardant insulation grade, etc. 2、PVC for sheathing. Polyvinyl chloride plastic sheath has good corrosion resistance, sufficient mechanical properties, certain atmospheric resistance, softness, vibration resistance, light weight, easy processing and laying. According to the use conditions of wire and cable, different types of PVC sheath materials have been researched and made: ordinary sheath level, cold-resistant sheath level, soft sheath level, heat-resistant sheath level, oil-resistant sheath level, easy-to-tear sheath level, anti-mold and anti-termites and anti-rodent sheath level, flame retardant sheath level, etc. 3, semi-conductive polyvinyl chloride (PVC) plastic semi-conductive PVC plastic can be used as shielding material, for example, as a shield for 10kV For example, it can be used as the shield of 10kV PVC cable. Semi-conducting plastics used as shielding material for high-voltage cables, because the semi-conducting material directly in contact with the insulation material, will occur mutual migration, so try to use the same plasticizer as the insulation material or good electrical properties, migration of small plasticizers. Otherwise, it will affect the electrical insulation performance of the insulating material in the process of use. 4, environmentally friendly anti-termites, anti-rat cable sheathing material termites and rats on the cable damage, light interruption of power supply, serious accidents, so that the power and communications sector by damage. In the past, the method of adding toxic additives (such as chlordane, heptachlor, dieldrin, aldrin, etc.) within the cable sheathing material was used to kill termites and rats in order to protect the safe operation of cables. However, these toxic additives can cause pollution and harm to the environment and people. At present, more use in the sheath material to add lead naphthenate or naphthenic acid ketone as additives to make a modified termite resistant sheath material. 5、Low smoke and low halogen type flame retardant sheathing material. With ordinary (flame retardant) PVC cable material manufactured by the cable burning will produce a lot of black smoke, while releasing a large amount of corrosive gas HC1, the human body and instruments and devices will cause great damage. Low smoke and low halogen flame retardant cable material is a high-tech product made of special PVC resin as the base material, adding various modifiers, auxiliaries and excellent flame retardants, and fully plasticized through uniform mixing and processing. It not only has excellent flame retardancy, but also releases low amount of smoke in combustion, and HC1 release is very low, which can be observed in the combustion flame and nearby objects. Compared with ordinary PVC sheathing material, its tensile strength and elongation at break are comparable; no special screw is needed for extrusion, and its process performance is comparable. The cables made with this cable material are fully applicable to places with high requirements for wire and cable flame retardant performance, such as subways, high-rise buildings, power stations, radio and TV centers and computer centers.

Application Recommendation